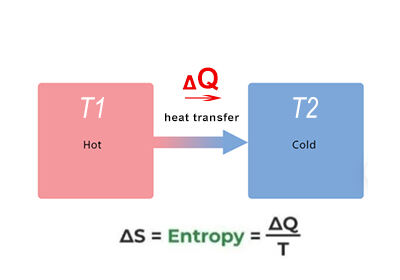

The natural laws of physics dictate that the energy in a system will always flow until equilibrium is achieved. there is a temperature difference, heat will  naturally transfer from the warmer body or fluid to the colder medium. The theory of heat transfer from one media to another, or from one fluid to another, is determined by several basic rules.

naturally transfer from the warmer body or fluid to the colder medium. The theory of heat transfer from one media to another, or from one fluid to another, is determined by several basic rules.

LAWS OF THERMODYNAMICS

a. Heat will always flow from a hotter medium to a colder medium.

b. There must always be a temperature difference between the media.

c. The heat lost by the hotter medium equals the heat gained by the colder medium, excluding any losses to the surrounding environment.

A heat exchanger follows the heat transfer theory to reach equalization, which continually transfers heat from one medium to another. There are two main types of heat exchangers:

a. Direct heat exchanger, where both media come into direct contact with each other without any mixing between them. A cooling tower is an example of this type of heat exchanger, where water is cooled by direct contact with air.

b. Indirect heat exchanger, where both media are separated by a wall through which heat is transferred. This method enables better regulation and optimization of the heat transfer procedure, improving efficiency and cost-effectiveness.

1. Plate heat exchanger working principle

There are several main types of indirect heat exchangers available, including plate, shell-and-tube, and spiral designs.in most cases, the plate type is typically the most efficient heat exchanger. Generally, t provides the optimal solution to thermal challenges, offering the widest range of pressure and temperature limits within the limitations of existing equipment.

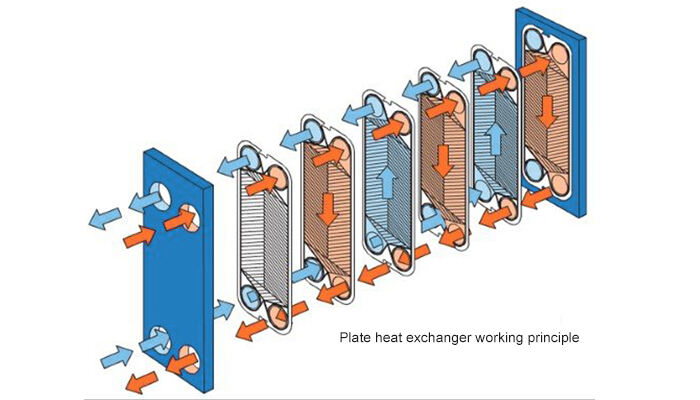

A plate heat exchanger consists of a number of heat transfer plates that are sandwiched between a fixed plate and a movable pressure plate to form a complete unit. Each heat transfer plate is equipped with a gasket arrangement, which creates two separate channel systems. The gasket arrangement, consisting of field and ring gaskets, results in through flow in single channels, allowing the primary and secondary media to flow in a counter-current manner.

The gasket design ensures that the media cannot mix. The plates are corrugated, which induces turbulence in the fluids as they pass through the unit. This turbulence, combined with the ratio of media volume to the size of the heat exchanger, contributes to an effective heat transfer coefficient.

Plate heat exchanger working principle

The heat transfer area of a plate-type heat exchanger is formed by the corrugated plates located between the frame and pressure plates, with gaskets acting as seals between the plates. The fluids flow counter-currently through the heat exchange, resulting in highly efficient thermal performance and allowing for a minimal temperature difference between the inlet and outlet of the service mediums. In cases where a heat-sensitive or viscous press is involved, the cold fluid is brought into contact with the hot liquid to minimize the risk of overheating or freezing the press. Plates are available with infamous pressing depths, chevron-angled patterns. and corrugated shapes, all designed to optimize performance, Each product range has specific plate features tailored to different applications, The distribution area ensures fluids flow to the entire heat transfer surface. This helps to avoid stagnant zones that may cause fouling.

>> Get Professional Design of PHE

2. Plate heat exchanger assembly steps

The plate heat exchanger is being installed

Step 1: The frame is put together. lt consists of frame and pressure plates, top and bottom carrying bars, and connections.

Step 2: The plates corresponding to the specifications are positioned in the frame.

Step 3: The tightening bolts are installed, and the plate pack is securely tightened using a spanner.

3. Plate heat exchanger advantages

a. The true counter-current flow design enhances thermal performance. Additionally, significantly less hold-up volume (up to 80-90% less).

b. Requires low capital investment and has lower installation costs compared to other heat exchanger types. The plates that have limited maintenance and operating costs can also be easily removed and replaced.

c. Plate heat exchangers are less prone to fouling, stress, wear and corrosion. This ensures the greatest reliability.

d. Consume less energy while delivering optimal process results, making them environmentally friendly.

e. Offer a wide range of operating pressures and temperatures.

4. Plate heat exchanger disadvantages

a. Poor sealing can lead to leakage, which can be a significant issue.

b. Have limited pressure capabilities, generally not more than 1.5MP.

c. When dealing with fluids containing suspended solids, there is a higher occurrence of blockages.

d. Unsuitable for gas-to-gas heat exchange.

e. Compared to shell and tube heat exchangers, plate heat exchangers are more susceptible to fouling.

5. Plate heat exchanger main types

( 1 ) Gasket Plate Heat Exchanger

A gasket plate heat exchanger (GPHE) is a type of heat exchanger that uses a series of corrugated plates held together by bolts. Gaskets are placed between each plate to create a series of flow channels. The plates are typically stainless steel, titanium, or other corrosion-resistant materials. Heat exchanger plates are corrugated to increase the surface area for heat transfer. Heat exchanger gaskets are used to seal the flow channels and prevent leakage. Plates are stacked and bolted together, creating a compact design. GPHEs are very compact compared to traditional heat exchangers. Plates can be easily rearranged to change flow patterns or heat transfer rates. GPHEs can be easily cleaning or inspected.

( 2 ) Welded Plate Heat Exchanger

A welded plate heat exchanger (WPHE) is a type of heat exchanger that utilizes a series of corrugated plates that are welded together to form a compact and robust unit. Unlike gasket plate heat exchangers (GPHEs), WPHXs do not rely on gaskets to seal the flow channels, eliminating the risk of leakage associated with gasket deterioration. The plates have a corrugated pattern, similar to GPHEs, to increase the surface area for enhanced heat transfer. The absence of gaskets eliminates a potential wear point, resulting in a longer operational lifespan. However, WPHEs typically have higher manufacturing costs than GPHEs. Modifying the flow patterns or heat transfer rates can be more challenging compared to GPHEs.

( 3 ) Plate and Shell Heat Exchanger

A plate and shell heat exchanger is a type of heat exchanger that uses a series of plates to transfer heat between two fluids. The plates are arranged in a stack, and the fluids flow through channels created between the plates. The shell is a larger container that surrounds the plate stack and contains one of the fluids. The plates are typically made of stainless steel, titanium, or other corrosion-resistant materials. They are corrugated to increase the surface area for heat transfer. The plates are typically made of stainless steel, titanium, or other corrosion-resistant materials. They are corrugated to increase the surface area for heat transfer. The flow channels are designed to minimize pressure drop, leading to lower pumping costs. However, Plate and shell heat exchangers can be more expensive than other types of heat exchangers, especially for larger sizes.

( 4 ) Bloc Plate Heat Exchanger

The Bloc Plate Heat Exchanger is a highly efficient and versatile heat exchanger designed for various applications. It's a type of plate heat exchanger that features a unique and robust design. The bloc design features a compact and space-saving configuration, allowing for a smaller footprint compared to traditional heat exchangers. The robust construction and durable materials minimize downtime and increase reliability. The high efficiency and low pressure drop contribute to reduced energy consumption and operating costs. Bloc Plate Heat Exchangers are more applicable to Crude Oil refinery, Fertilizer Industry, Inorganic Chemicals, Oil and Gas, etc.

( 5 ) Semi-welded Plate Heat Exchanger

A semi-welded plate heat exchanger (Semi-welded PHE) is a type of heat exchanger that combines the features of both gasket plate heat exchangers (GPHEs) and welded plate heat exchangers (WPHEs). It utilizes a combination of welded and gasketed plates to achieve a balance between high pressure capability, flexibility, and cost-effectiveness. Plates are partially welded together to create a more robust and leak-proof design compared to GPHEs. The remaining sections are sealed with gaskets. Gaskets are used to seal the non-welded sections of the plates, providing flexibility for flow pattern adjustments and plate replacement.

By understanding the different types of plate heat exchangers available, you can make an informed decision and select the one that best meets your specific requirements. If you have any inquiries about plate heat exchangers or need help selecting one for your specific requirements, please feel free to reach out to us. Our team of experts is readily available to provide you with the necessary support and guidance.

( 1 ) Plate Heat Exchanger Plate selection: The plate height or channel gap is determined by striking a balance between thermal difficulty and available pressure drop. Generally, a taler plate heat exchanger with a narrower channel gap offers higher thermal efficiency, making it suitable for applications requiring close approach temperatures.

( 2 ) Plate Heat Exchanger Gasket selection: When there are permanent changes in operating temperatures and pressures, or if another medium is to be processed in the plate heat exchanger, careful consideration should be given to the selection of gasket material. We can supply all brands of PHE Gaskets the NBR, EPDM, HT-NBR, HT-EPDM, HNBR, VITONA/G, and LLR.

Choosing the right plate heat exchanger manufacturer is crucial. It ensures you receive a product that is reliable, efficient, and cost-effective. This translates into reduced operating costs, minimized downtime, and optimal performance for your specific application. A reputable manufacturer will have the expertise to design and build a heat exchanger that meets your exact requirements, providing long-term value and peace of mind.

We understand that every application is unique. JINFAN has been developing plate heat exchanger technology and products customized and specific applications to our client's specifications and application needs. We design and manufacture plate heat exchangers used in applications such as heating, cooling, sterilization, pasteurization, heat recovery, condensation, and evaporation in various industrial processes for chemicals, food, air conditioning, marine, pulp and paper, pharmaceuticals, steel/metal, and related.

Our plate heat exchangers are meticulously engineered to deliver optimal heat transfer performance, minimizing energy consumption and maximizing efficiency. We offer the widest range of plate heat exchangers including complete units and replacement spare parts that are suitable for all types of industries. Our factory has more than 400 sets of OEM plate molds, with plate areas of 0.03m' to 3m, and ports from p28 to p650. We can supply all brands of PHE plates that ss304, 316, Titanium, Tipd, Hastelloy C276, c2000, and Nickel, etc. We are constantly looking to expand and upgrade with new performance criteria and greater flexibility.

JINFAN is committed to sustainability, offering energy-efficient heat transfer solutions that contribute to a greener future.

1. Gasket Plate Heat Exchanger

The gasket plate heat exchanger produced by JINFAN employs a sophisticated manufacturing process that includes precision stamping and welding of high-quality plates, ensuring optimal alignment and minimal leakage. The use of durable materials, such as stainless steel and specialized polymers for gaskets, enhances resistance to corrosion and thermal stresses, thus extending the lifespan of the exchanger. Furthermore, the gasketed design enables simple disassembly for cleaning and maintenance, minimizing downtime.

_________

2. Welded Plate Heat Exchanger

The welded plate heat exchanger produced by JINFAN features advanced manufacturing techniques that involve laser welding or electron beam welding to join the plates, ensuring a strong, leak-proof design. Constructed from high-quality materials like stainless steel, these exchangers offer excellent resistance to corrosion and high-pressure conditions, making them suitable for demanding applications. The welded design allows for a more compact structure, enhancing heat transfer efficiency by creating a larger surface area in a smaller footprint. This reduces the amount of fluid needed and improves overall thermal performance.

_________

3. Semi-welded Plate Heat Exchanger

The semi-welded plate heat exchanger produced by JINFAN combines the advantages of both welded and gasketed designs. This innovative solution features a unique construction where every other plate is welded, providing excellent leak resistance for high-pressure applications while allowing for easy maintenance through the gasketed plates. Constructed from robust materials like stainless steel, the semi-welded design offers exceptional corrosion resistance and thermal efficiency. The welded sections enhance structural integrity, making it ideal for handling aggressive fluids. The gasketed areas facilitate straightforward disassembly for cleaning, optimizing operational uptime.

_________

The bloc plate heat exchanger produced by JINFAN is a compact, integrated solution that combines the functionalities of multiple heat exchangers into a single unit. This innovative design minimizes space requirements while maximizing thermal efficiency, making it ideal for applications with limited installation space. Constructed from high-quality materials, such as stainless steel, the bloc PHE offers excellent resistance to corrosion and high temperatures. Its unique configuration ensures optimal heat transfer by enhancing fluid dynamics and reducing pressure drop, leading to improved energy efficiency.

_________

5. Plate & Shell Plate Heat Exchanger

The Plate & Shell heat exchanger produced by JINFAN combines the benefits of traditional plate and shell designs, offering superior thermal efficiency and compactness. This innovative construction features corrugated plates enclosed within a cylindrical shell, allowing for enhanced heat transfer while maintaining a robust and durable structure. Manufactured from high-quality materials like stainless steel and nickel alloys, these heat exchangers provide excellent resistance to corrosion and high-pressure conditions, making them suitable for a wide range of demanding applications. The design minimizes thermal stress and allows for effective handling of viscous fluids.

_________

6. Multi-section Pasteurizer Plate Heat Exchanger

The Pasteurizer Plate Heat Exchanger produced by JINFAN is specifically designed to meet the rigorous demands of pasteurization processes in the food and beverage industry. Its innovative design features specially crafted corrugated plates that enhance heat transfer efficiency while maintaining a compact footprint. Constructed from high-quality stainless steel, the exchanger offers excellent resistance to corrosion and high temperatures, ensuring durability and compliance with hygiene standards. The smooth surfaces of the plates facilitate easy cleaning, minimizing the risk of contamination and ensuring optimal sanitation.

_________

7. Wide Gap Plate Heat Exchanger

The Wide Gap Plate Heat Exchanger produced by JINFAN is engineered for handling fluids with higher viscosity and solid content, making it ideal for applications in industries such as food processing, chemical manufacturing, and wastewater treatment. Its innovative design features wider spacing between plates, allowing for efficient flow of challenging fluids while minimizing clogging. Constructed from durable materials like stainless steel, the heat exchanger ensures excellent corrosion resistance and longevity, even in harsh operating conditions. The unique plate design not only enhances thermal efficiency but also facilitates easy cleaning, making maintenance straightforward and reducing downtime.

_________

8. Plate Evaporator & Condenser

Constructed from high-quality materials like stainless steel, the evaporator offers excellent resistance to corrosion and high temperatures, ensuring durability and reliability in demanding applications. The compact design allows for easy installation and integration into existing systems, optimizing space utilization. Made from high-quality materials such as stainless steel, the condenser ensures excellent corrosion resistance and durability, even under demanding operating conditions. The design allows for optimal flow dynamics, reducing the risk of fouling and ensuring consistent performance.

_________

JINFAN offers customizable thermal designs, ensuring optimal thermal performance with minimal pressure drop. Always consult JINFAN for the right selection of the plate heat exchanger model, and to help with the most favorable price.

>> Plate heat exchanger In HVAC systems

With more than 30 years of experience in designing and manufacturing Plate Heat Exchanger & PHE replacement spare parts, JINFAN PHE has a lot of knowledge about each Plate Heat Exchanger type. When it comes to Spare Parts for Plate Heat Exchangers, our products are perfectly fully compatible with PHEs of all brands of both material and dimensions.