With 30+ years of plate heat exchanger production and R&D experience, JINFAN is committed to developing optimized and continuous process flow for your application. Our team is experienced & knowledgeable practitioners of the heat exchanger industry. We provide customized solutions for industrial users to better achieve heat transfer and energy saving. <p><strong>Learn more about JINFAN PHE's solution to make better choices.</strong></p>

Every sewage treatment project is unique. JINFAN customizes the right heat exchanger solution to efficiently utilize energy, reduce operating costs. Contact us now to make your sewage treatment system more energy-efficient and reliable!

Industrial Waste Heat Recovery (WHR) refers to the process of capturing and reusing heat that would otherwise be lost from industrial processes. Many industries generate significant amounts of waste heat during operations, such as from hot gases, liq...

A welded plate heat exchanger is a high-performance heat transfer device designed to handle demanding applications involving high pressures, high temperatures, or aggressive fluids. Unlike traditional gasketed plate heat exchangers, the welded design...

A semi-welded plate heat exchanger is designed for efficient heat transfer between two fluids while offering enhanced durability and flexibility. It combines welded and gasketed plate construction to achieve optimal performance in demanding applicati...

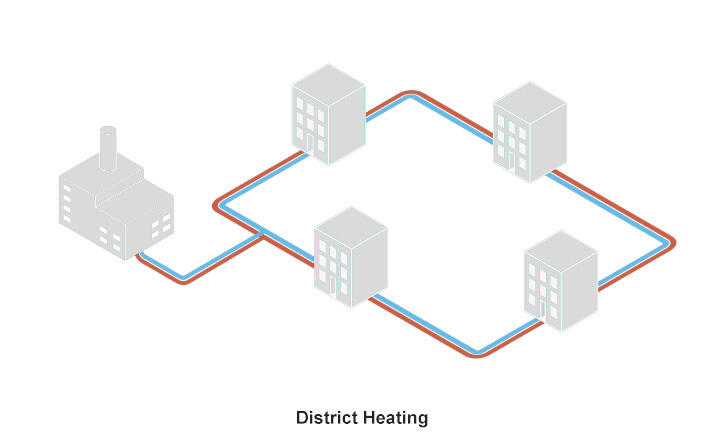

Plate heat exchangers (PHEs) are critical components in district heating systems due to their high efficiency, compact size, and adaptability to varying operational conditions. Below is a detailed explanation of their typical applications: 1. Central...

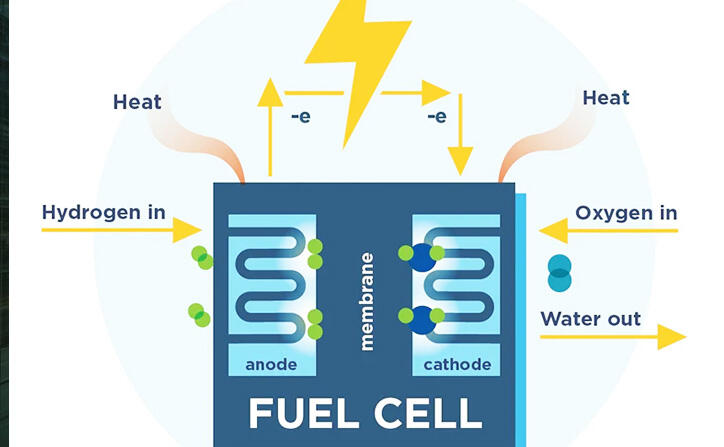

Alkaline hydrogen electrolyzer is an important supporting technology for hydrogen fuel cell systems. By producing clean, renewable hydrogen, they enable applications across a wide range of sectors including transportation, power generation and energy...

By exploring the relationship between data centre operations and the environment, JINFAN devotes itself to more green data centres and catalyze a shift toward more sustainable practices that paves the way for a greener and more responsible digital future.

Petrochemicals sometimes abbreviated as petchems are the chemical products obtained from petroleum by refining. Some chemical compounds made from petroleum are also obtained from other fossil fuels, such as coal or natural gas, or renewable sources s...

Ammonia has been known for more than 200 years. The production of significant quantities of ammonia using the cyanamide process did not occur until the early 20th century. Ammonia production is a vital industrial process that involves the synthesis o...

Plate heat exchangers demonstrate effectiveness and durability in managing corrosive substances. Due to their design, JINFAN heat transfer solutions enhance the efficiency of key for the Iron And Steel Industry.

The plate heat exchanger is comprised of a series of corrugated metal plates for the passage of two liquids for heat exchange. With a vast array of equipment and extensive expertise in processes accumulated over many years, JINFAN offers heat transfer solutions to enhance the efficiency of multiple processes in your paper production.

The HVAC Plate Heat Exchanger is a device employed for transferring heat between two distinct fluids. Constructed from thin metal plates boasting high surface area and excellent thermal conductivity that enable efficient heat transfer. The design of ...