Looking for phe plate and frame heat exchanger condenser? Then JINFAN is just right.

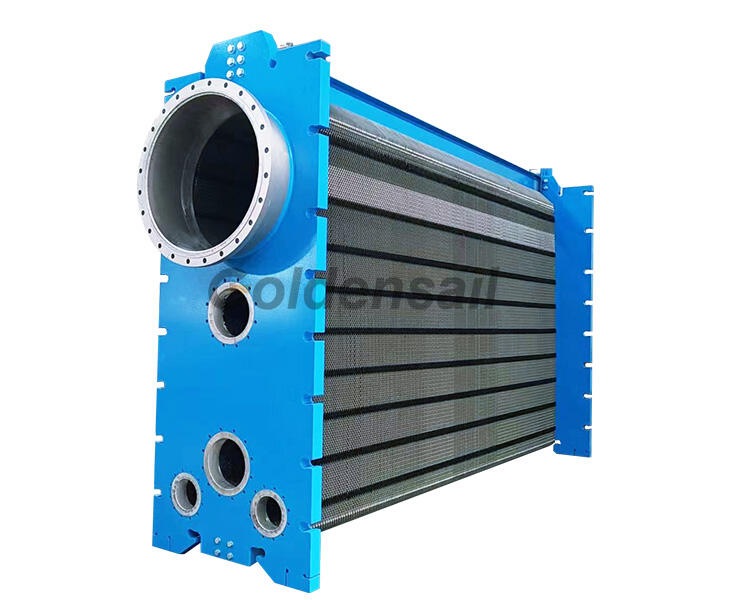

We are a first-class plate heat exchanger condenser manufacturer & supplier. A plate condenser is a heat exchanger designed for the condensation of vapor into a liquid. It consists of plates with channels through which the vapor flows, facilitating efficient heat transfer and condensation. Plate condensers are widely used in various industrial applications and offer advantages such as compact size, high heat transfer efficiency, and easy maintenance.

A plate condenser is a type of heat exchanger used to condense vapor into a liquid. It consists of a series of plates with channels through which the vapor flows. As the vapor comes into contact with the cool surface of the plates, it condenses, releasing heat to another fluid or the surrounding environment. The plates in a plate condenser are typically made of stainless steel or other corrosion-resistant materials. They are arranged in a parallel or counterflow configuration to maximize the heat transfer efficiency. The plates have a large surface area, allowing for a high heat transfer rate and efficient condensation.

In operation, the vapor to be condensed is introduced into the plate condenser and flows through the channels between the plates. The plates are cooled either by direct contact with a cooling medium or by indirect heat transfer through a separate fluid. As the vapor comes into contact with the cool plates, it loses heat and condenses into a liquid.

The condensed liquid collects at the bottom of the condenser and is drained out. The cooled vapor exits the plate condenser, either as a gas or as a partially condensed liquid. The condensate can be further processed or collected for various purposes, such as product recovery or environmental compliance.

Plate Condenser

JINFAN‘s strong technical team provides custom design solutions for plate condenser system according to different cooling capacities and operational conditions. Our company focuses on creating energy-efficient designs, uses high-quality materials, such as stainless steel, titanium, and corrosion-resistant alloys that ensure optimal performance and efficiency for each unique application. We also provide modular plate condensers that are expanded by adding more plates to accommodate increased capacity or modified to suit changing process requirements.

When choosing a plate condenser manufacturer, it's important to consider the experience in the relevant industry, the quality of designs, and the ability to provide comprehensive after-sales support to ensure long-term system performance. Jinfan has nearly 30+ years of experience in designing and manufacturing plate heat exchanger. We specialize in designing, producing, and supplying gasketed, welded, evaporator and condenser heat exchangers. Our plate condensers are commonly used in Marine, Chemical Industry, Petrochemical Power, Biopharmaceutical, etc.