Looking for a Double Wall Plate Heat Exchanger for environmental protection? Then JINFAN is just right.

We are a first class plate heat exchanger manufacturer & supplier. With many years of R&D experience, JINFAN double wall plate heat exchanger combination has resulted in the most optimal heat transfer solution for industrial.

Other types of plate heat exchangers

Double wall heat exchanger plates and gaskets

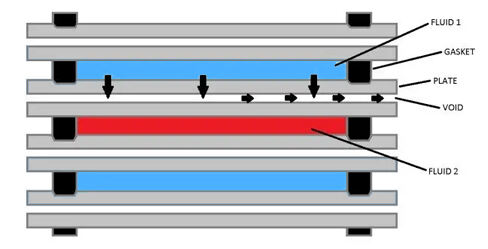

Double wall plate and frame heat exchangers are security-type exchangers, having a peculiar construction with a double plate, hence their name "double wall". Although the design of the Double Wall GPHE is different from the traditional heat exchanger, the working principle is similar. The double-wall design ensures that the mixing between the primary and secondary fluid is avoided even in case of breaking or cracking of a plate, due to corrosion or other causes. Moreover, any leakage from either fluid within the heat exchanger is visible on the outside, therefore, the operation can be stopped for maintenance.

JINFAN is one of China's leading manufacturers and suppliers of double wall plate and frame heat exchangers. Contact us to get double wall plate heat exchanger pdf

Double Wall Heat Exchanger Plate

Plate Material |

Suitable Media |

Stainless Steel(304/316) |

Pure Water, River Water, Edible Oil, Mineral Oil |

Ti, Ti-Pd |

Seawater, Brine, Salt Substance |

20Cr,18Ni,6Mo(254MO) |

Dilute Sulfuric Acid, Dilute Salt Substance Aqueous Solution, Inorganic Aqueous Solution |

Ni |

High Temperature, High Density Caustic Soda |

Hastelloy(C276,D205,B2G) |

Concentrated Sulfuric Acid, Hydrochloric Acid, Phosphoric Acid |

Operating Temperature |

Suitable Media |

|

NBR |

-20℃-+110℃ |

Water, sea water, mineral oil, Salt, Brine |

EPDM |

-50℃-+150℃ |

Hot water steam, Acid, Alkali |

HNBR |

-15℃-+160℃ |

High temperature, mineral oil, water |

VITONA/VITONG/FKM |

-35℃-+180℃ |

High temperature, high resistance, strong oxidants, oil, acid, alkali, etc |

__